Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Software

System

Ideal for a multi-user or multi-experiment setting, or future-proofing the system. Side loading Secondary Inserts can be exchanged between Proteox systems enabling experiments to be set up on a workbench prior to exchange. This is a significant advantage for optical experiments where alignment of components can be performed outside of the system.

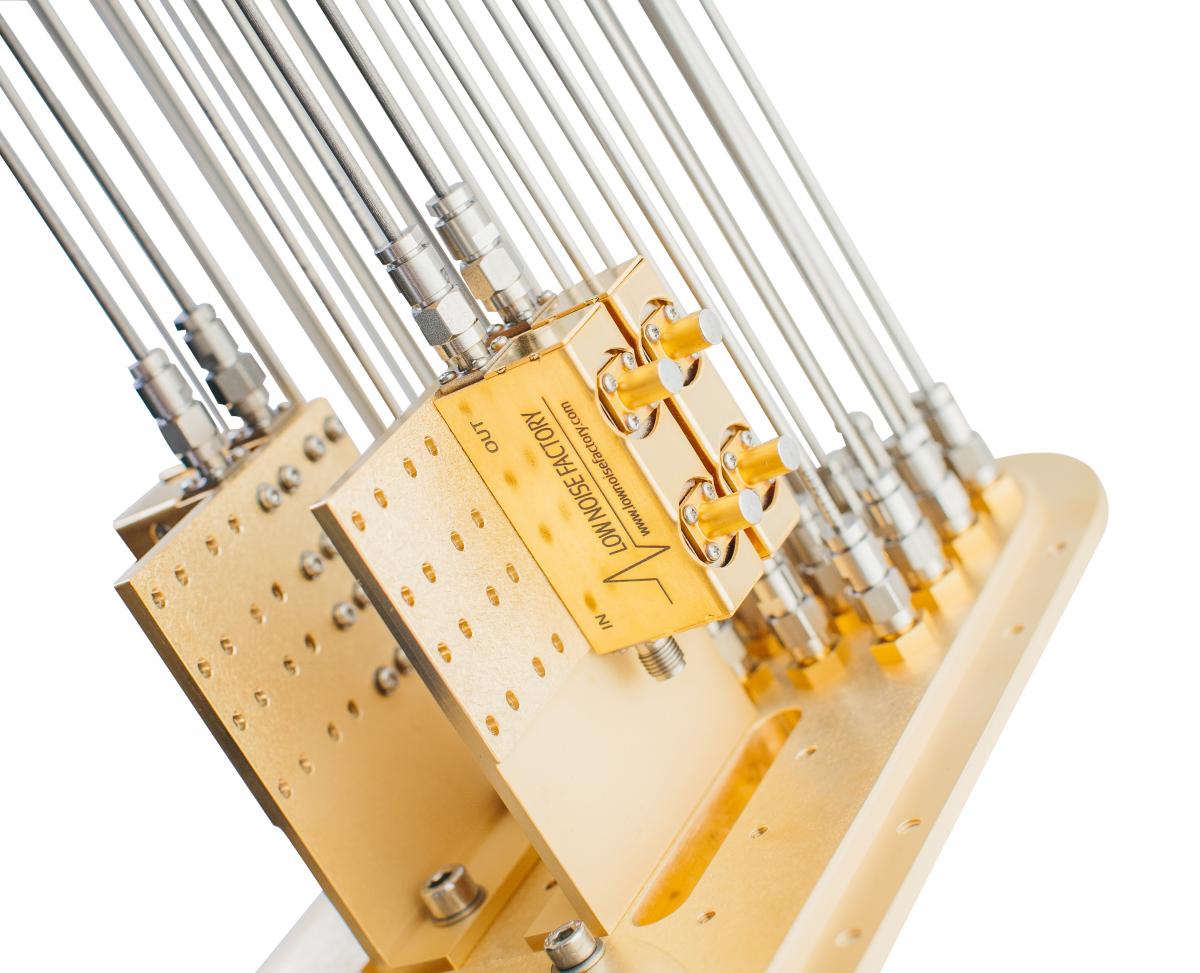

Utilise a custom Secondary Insert for an optimised experiment, ready to run on system arrival by incorporating cold electronics such as circulators and amplifiers, directly during manufacture. All mounted hardware and components are factory installed.

Moving beyond standard access ports, the Secondary Insert can accommodate full experimental set-ups, including DC wiring, coaxial wiring and signal conditioning components.

Standard options:

ISO100-2

A standard configuration of 2 x ISO100 ports, with multiple ISO100 options to provide experimental wiring.

BLL-60

BLL-72

Optional Blank Plates Instead Of SI

Custom Secondary Insert option:

Flexible Wiring

Attenuators

Attenuators can be selected per line and per plate; 0 dB attenuators for conductor thermalisation; 3 dB, 6 dB, 10 dB and 20 dB attenuators.

Low-pass multi-stage filters can be mounted for use at temperatures to below 100 mK.

Our patented bottom loader and active gas gap heat switch technology enable fast sample turnaround times with sample puck cooldown times in less than 8 hours, particularly suited to magnet systems and for qubit screening. For the ProteoxMX, the sample loader is integrated onto a Secondary Insert, including hermetic feedthroughs and thermalisation hardware for provision of experimental wiring.

Customised Magnets