Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Dr Martin Jackson

Cryogenic Engineering Team Leader at Oxford Instruments NanoScience

Dr John Burgoyne

Head of Product and Marketing at Oxford Instruments NanoScience

"Dark matter" is one of the most fundamental mysteries of our universe, making up an estimated 85% of the total mass of the universe compared to the 15% mass we see and experience. Not only that, but in the most accepted physics model of the universe, only 5% of the total mass-energy content (remembering that mass and energy have Einstein’s famous E = mc2 equivalence!) is visible mass like the planets, stars and galaxies we see, ~27% is dark matter, and ~68% is dark energy. It is little wonder then that observing and characterising dark matter is one of the major physics goals of today, and one with several theories that experimentalists seek to prove – or even eliminate – through observation.

In this blog, our Cryogenic Engineering Team Leader, Dr Martin Jackson, and our Head of Product and Marketing, Dr John Burgoyne, discuss recent testing of our Proteox dilution refrigerator system for a dark matter experiment.

There are many candidates for the type of particle that dark matter is. Not all require the millikelvin temperatures of a dilution refrigerator for their detection mechanisms, but those involving so-called axion detection and the dark-matter-related neutrino detection need such extremely low temperatures for their detection mechanisms in order to remove noise sources in tiny signals.

We have a number of our Proteox dilution refrigerator systems engaged in dark matter searches of both types – in axion search using the "haloscope" arrangement of a cold microwave cavity coupled with a superconducting magnet, and in neutrino experiments with heavy shielding to remove background radiation.

In this particular instance, our customer needs to suspend a 250 kg lead (Pb) shield from the mixing chamber plate to shield their detectors from intrinsic background radiation. In fact, to achieve this low background the shield is made of Roman-era lead.

The reason Roman lead is used is because it has a relatively low intrinsic radioactivity compared to modern lead. The Roman lead – which has been sensitively recovered from a Roman shipwreck off the coast of Sardinia – is now free from the radioactive isotope Pb-210, which has a relatively short half-life and so has long ago decayed [1, 2].

Scientists who are interested in dark matter might typically be developing extremely sensitive detectors, and for that reason they want to have a calibrated source, with no intrinsic background or any other sources of interference that could in principle affect their measurements.

Aside from such specialised experiments, another reason for Proteox to be capable of bearing a large load is simply that many researchers are performing large numbers of experiments, where the total mass of their equipment and samples may add to a significant amount. They need to be confident that their dilution refrigerator will be able to support all that.

We have supplied several systems with high load-bearing capability for both of these reasons.

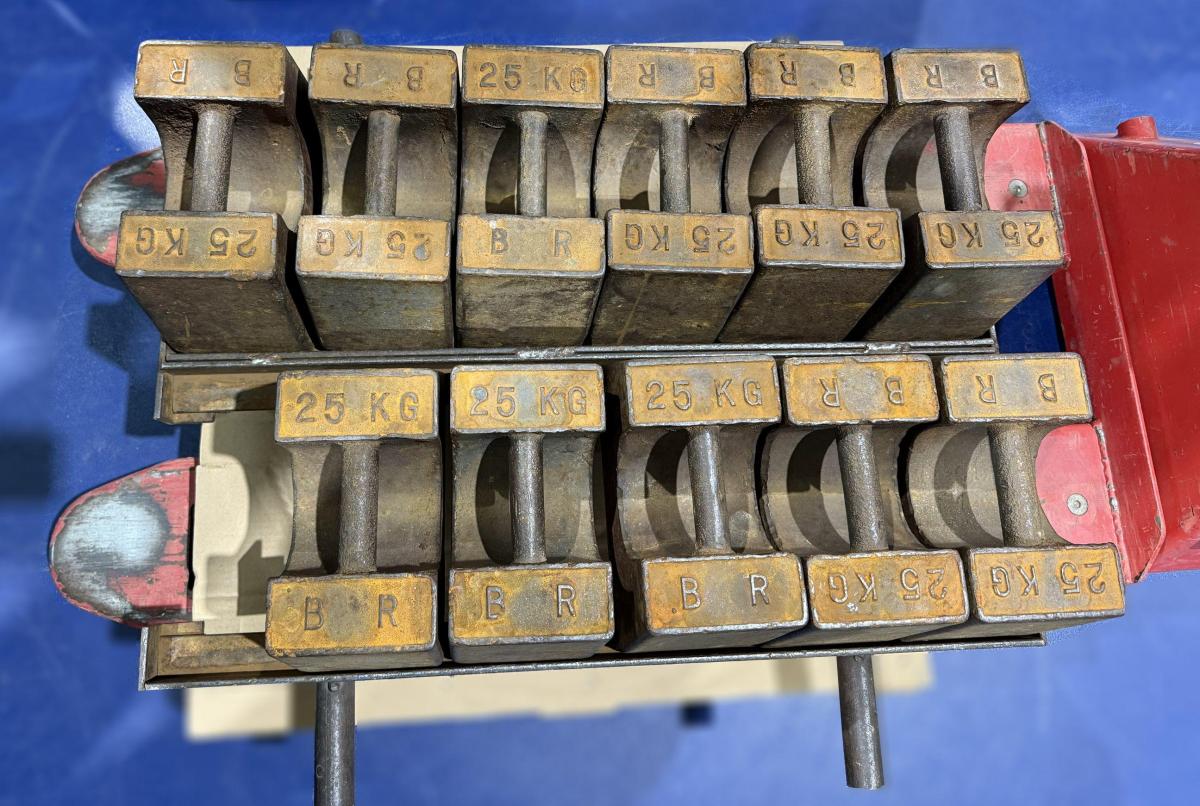

In this instance the requirement was 250 kg, and the system was physically tested to > 280 kg to ensure a safe allowance.

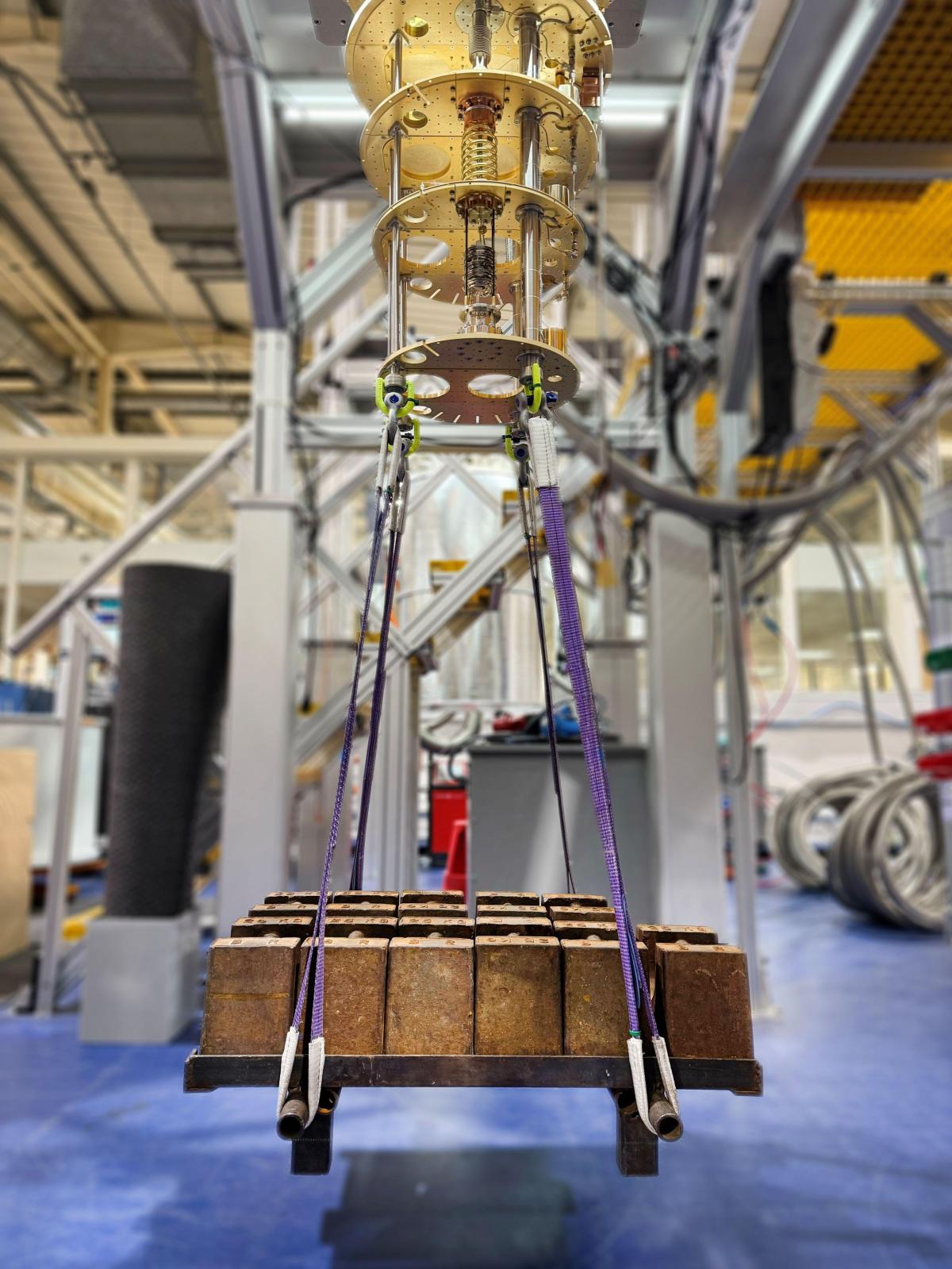

It is important to emphasise here that supporting such an extreme load does not involve any modifications to the standard Proteox structure; rather, a specially-designed mounting is fixed to the standard mixing chamber plate (the coldest stage of the dilution refrigerator, generating < 10 mK).

This arrangement is a multi-point mounting system located directly beneath the Proteox support structures including our proprietary gas-gap heat switches that aid fast cool down.

In preparation for the real-life physical mass test, we performed load bearing calculations based on a systematically distributed payload mounted using these points.

The physical test then involved applying such a distributed test load suspended on the mounting system; as you would expect, we strongly recommend customers to follow this even distribution of mass methodology.

We performed preliminary structural load and screw-thread-engagement calculations, FMEA (Failure Mode and Effects Analysis) and other simulations, and held formal design reviews which all gave us confidence in our solution and that a physical test would be safe to perform in our factory. Eventually of course, the proof is the real-life test!

The result of that test up to 280 kg, performed and certified by an accredited lifting solutions provider, proved this remarkable result, and the resulting formal documentation is what we can provide our customer. Ultimately, that real-life test confirms theoretical calculations but gives tangible evidence which is much more robust and reliable.

Measuring deformation directly can be quite difficult, but because the system and its wiring connections are very sensitive to any changes in geometry, we would see short circuits and malfunctions if any deformation was present. We performed the load measurement before cooling down the system, and then once cold put it through our full test and validation procedures to confirm that it remained functional to our high standards, demonstrating no significant deformation.

In principle, one could do a type-test on a single or small number of systems and then self-certify, but testing each system fully gives the complete confidence that we want our customer to have.

As mentioned above, the support structures in this system are identical to those across our standard Proteox systems. The only adaptation for the large load capability is the specific mounting mechanism installed on the underside of the mixing chamber plate, so this can be provided to existing Proteox customers who wish to extend their experiments in these dark matter and cosmology applications. While we are aware that very large fridges have been designed specifically for such purposes, we do not believe there are any others in this class of standard cryogen-free dilution refrigerators that have been adapted or tested in this way.

We are! Providing that the payload is mounted and distributed symmetrically with full engagement within the bolting and mounting parts, we can have that long term confidence. The large payload will not affect the lifetime of the system, or the base temperature. The only parameter significantly affected is obviously the cool-down time, due to the extra thermal mass to be cooled. The other aspects of system performance will not be affected.

Dark matter is one of the great unsolved problems in physics. There was great excitement in detecting the Higgs boson, but we still need to find out what that vast majority of the universe is actually made of. There are many hypothesised dark matter particle candidates, and whoever detects them first is almost certainly guaranteed a Nobel Prize! So-called "Big Physics" may seem esoteric, but it speaks to a core desire to better understand the universe we inhabit.

We bring experience and expertise as low-temperature physicists and engineers ourselves, and work closely with customers to understand their requirements. Having effective solutions such as this which are built on our standard Proteox systems mean that we can achieve shorter delivery times and more cost-effective solutions for customers compared to an extremely large custom-designed dilution fridge.

And of course, we continuously focus on quality and engage in thorough testing such as that we have described here, so that we and the customer are assured that no product leaves our factory unless we know it performs to its full specification.

Contact us to learn more about the Proteox family of dilution refrigeratorsReferences:

[1] A. Alessandrello, C. Cattadori, G. Fiorentini, E. Fiorini, G. Gervasio, G. Heusser, G. Mezzorani, E. Pernicka, P. Quarati, D. Salvi, P. Sverzellati, L. Zanotti, “Measurements on radioactivity of ancient roman lead to be used as shield in searches for rare events” Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, Volume 61, Issue 1, 1991, 106-117. doi: https://doi.org/10.1016/0168-583X(91)95569-Y

[2] Rosie de Laune, From shipwreck discovery to supernova detection, 2025. https://www.isis.stfc.ac.uk/Pages/SH25_RomanLead.aspx