Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

With the continued scale-up of solid-state quantum computing with superconducting or spin qubits at millikelvin temperatures, not only is cooling power important at the millikelvin stage where the quantum processor sits, but also the cooling power that is available at higher temperatures and more specifically 4 K. As qubit numbers increase, high 4 K cooling power is required to intercept the heat load from the significant amount of wiring, and to support cold electronics.

A well-designed dilution refrigerator optimises its cooling capacity across its multiple stages, so gaining cooling power performance at both the millikelvin and upper stages. Recent measurements on the 4 K stage of Oxford Instruments NanoScience’s ProteoxLX system, as a quantum computing scaling platform, demonstrate this.

In this blog Dr Tony Matthews, Measurement and Applications Technology Manager, and Dr Gustav Teleberg, Senior Technical Sales Engineer, explore these high cooling powers for quantum applications.

Firstly, for the basic operation of the system, thermal equilibrium is reached at each of the temperature stages when the cooling capacity at that stage balances the heat load on it. In order for a cryogen-free dilution refrigerator to operate it must be pre-cooled to a sufficiently low temperature, using a pulse tube refrigerator (PTR) with two cooling stages of “PT1” at approximately 40 K, and “PT2” nominally at 4 K, subject to the heat load. These PTR-cooled stages are then the basis for cooling power at a range of lower temperature stages moving down the dilution refrigerator structure that many people are now familiar with, ultimately to the < 10 mK stage of the dilution refrigerator mixing chamber plate.

Secondly and most importantly for real-world applications, especially including quantum computing, higher heat loads are generated by experimental services for a research system, or the array of input/output/control lines for a full-stack quantum computer, plus the addition of cold electronics such as amplifiers. As qubit numbers and therefore the number of such lines and cold electronic elements increases, depending on the qubit type deployed, the critical question becomes how much can be added to a system before performance is impacted.

For quantum computing applications, this question was addressed in the initial work of Krinner et al. [1] which spurred the optimisation of cryogenic systems for the installation of ever larger numbers of qubits. This work found a bottleneck at the cold plate, the intermediate plate usually installed between the still and mixing chamber of a dilution refrigerator which is cooled by the 3He outflowing from the mixing chamber to the still. Novel solutions for improving the cooling capacity of this stage were subsequently developed and deployed to commercial dilution refrigerators by Oxford Instruments NanoScience [2], thus removing that cooling bottleneck.

Dr Tony Matthews

Measurement and Applications Technology Manager at Oxford Instruments NanoScience

Dr Gustav Teleberg

Senior Technical Sales Engineer at Oxford Instruments NanoScience

ProteoxLX with secondary inserts

More recently Raicu et al. [3] highlighted the PT2 (nominally 4 K) stage as the limiting stage in their measurements. The cooling capacity available at the PT2 stage is set by two main factors: first, the baseline cooling power available from one or more PTRs. Secondly, how strongly coupled the dilution refrigerator system is to the PTR(s); this can be a contradictory requirement – strong thermal coupling is desired to attain the best possible thermal contact and therefore the highest cooling capacity, but strong thermal coupling may imply strong mechanical coupling which is often unwanted as the PTR can also be a source of mechanical noise.

Finally, a crucial factor is the sensitivity of the dilution refrigerator condensation stage to the precise PT2 temperature – often dictated by the design of the 3He pre-cooling heat exchangers and circulation system.

The desire to achieve higher cooling capacities at the PT2 stage has led some manufacturers to offer 'enhanced' versions of their systems with the aim of raising the available cooling capacity at this stage. However, for comparison it is worth looking at what a well-engineered system such as the ProteoxLX delivers as standard.

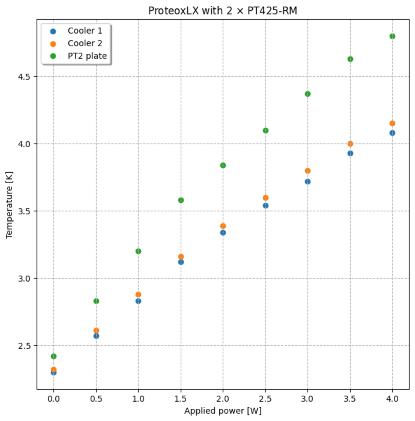

Data are shown below from recent measurements of the temperature of the ProteoxLX PT2 (4 K) stage plate compared to the second-stage (PT2) temperatures of the two pulse tube coolers fitted to the system, with varying heat loads applied using an electrical heater to simulate the impact from wiring, etc. The ProteoxLX continued to supply > 25 μW of cooling power at 20 mK at the mixing chamber stage throughout the test.

It is clear from these data that > 4 W of power – additional to the intrinsic static heat load – can be applied to this completely standard system without impacting the operation of the dilution refrigerator: more than double the value possible with other platforms.

This performance is already available on the core Proteox design, for all models including our largest commercial-scale ProteoxQX platform of which we recently announced the first two installations. There is no need for additional cost or complexity to enhance it further. Because pulse-tube integration is done in the same way across all variants of Proteox, all customers benefit from class-leading thermal performance and class-leading vibration performance at the same time. Some may need the extra power in their immediate use case, while others may simply want to future-proof their investment and not worry about having to upgrade their system as requirements evolve over time.

The superior 4 K cooling power of Proteox makes it easier to scale quantum computers. The number of signal lines can be increased further before the 4 K power becomes a thermal bottleneck compared to other systems. Its more efficient thermal design also means a less powerful pulse-tube cooler (or fewer pulse-tube coolers) is required for a given qubit-count quantum computer, which minimizes the overall power consumption of the system. Because pulse-tube coolers are both expensive to run and a significant source of vibrations, the Proteox platform becomes more cost effective and provides better noise performance as the number of qubits increase. In summary, Proteox makes better use of the available pulse-tube power through optimised system integration.

The Proteox family of dilution refrigerators provide solutions across the quantum eco-system from materials characterisation and device development on the compact ProteoxS, to the scalable quantum computing platforms of ProteoxMX, ProteoxLX, and ProteoxQX which leverage our side-loading interchangeable secondary inserts to enable cross-platform transfer of control wiring schemes.

Want to know more?

Contact us to learn more about the Proteox family of dilution refrigeratorsReferences:

[1] Krinner, S., Storz, S., Kurpiers, P., Magnard, P., Heinsoo, J., Keller, R., Lütolf, J., Eichler, C. and Wallraff, A. (2019). Engineering cryogenic setups for 100-qubit scale superconducting circuit systems. EPJ Quantum Technology, 6(1). doi: https://doi.org/10.1140/epjqt/s40507-019-0072-0

[2] Poole, T., Marsh, T. and Matthews, A.J. (2022). Optimal cooling configurations for quantum information processing at milli-kelvin temperatures. Cryogenics, 126, p.103538. doi: https://doi.org/10.1016/j.cryogenics.2022.103538

[3] Raicu, N., Hogan, T., Wu, X., Vahidpour, M., Snow, D., Hollister, M. and Field, M. (2025). Cryogenic Thermal Modeling of Microwave High Density Signaling. doi: https://doi.org/10.48550/arXiv.2502.01945