Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Dr Tony Matthews

Measurement and Applications Technology Manager at Oxford Instruments NanoScience

Dr Gustav Teleberg

Senior Technical Sales Engineer at Oxford Instruments NanoScience

In our previous blog, we explored how the Proteox dilution refrigerator design decouples millikelvin performance from the precise temperature of the second stage of the pulse tube cooler (PT2). This architectural choice unlocks a range of practical benefits for experimental physicists and quantum engineers alike.

One of the key advantages of this design is operational flexibility. Users can modify or reconfigure their experimental setups without jeopardising the performance of the fridge. This is particularly valuable in dynamic research environments where experimental demands evolve rapidly.

Moreover, the system can operate effectively even when the plate coupled to the second stage of the pulse tube cooler (the PT2 stage) runs at elevated temperatures. This is a significant departure from traditional systems, where tight thermal constraints often limited design freedom.

The PT2 stage is often referred to as the '4 K' stage, however in cryogen-free dilution refrigerators this is not defined by a single, fixed temperature. The operating point is set by a combination of:

Historically, 4.2 K was a natural reference point due to the use of liquid helium in wet systems. However, in modern cryogen-free systems, this temperature is no longer a hard constraint.

Applications with substantial heat loads: such as optical experiments involving large radiation inputs through windows or those dissipating power in cryo-CMOS devices running at the '4 K' stage stand to benefit from the enhanced cooling power at PT2. In these scenarios, the exact PT2 temperature is less critical than the ability to dissipate heat efficiently.

Another compelling use case is in the integration of lower-field magnets specifically designed for higher operating temperatures – something we are able to do due to our in-house magnet engineering, assembly and integration expertise. For instance, operating a magnet at 6 K instead of 4 K can shift the available power budget from ~2 W to ~8 W. This allows for more cost-effective cooling solutions without the need for additional pulse tube refrigerators (PTRs), which would otherwise significantly increase system complexity and expense.

Efficient handling of high heat loads at the 4 K stage requires careful thermal engineering. Most systems circulate 3He using room-temperature pumps, making heat exchanger performance critical. The returning gas must be precooled as close as possible to the PT2 temperature. This is typically achieved through:

If well-designed, these systems can operate effectively even when the PT2 stage exceeds 4 K.

Following the counterflow exchanger is the primary impedance of the dilution circuit. In wet systems, this ensured the return stream was at sufficiently high pressure for liquefaction of 3He via the 1 K pot. In cryogen-free systems, the impedance acts as a throttling valve, leveraging the Joule-Thomson effect to cool the 3He stream before final condensation in the still.

To maintain effective circulation and cooling at the millikelvin stage, the circulation system must support 3He flow rates around 2 mmols-1 with an inlet pressure of around 1 Pa and exhaust pressures up to 200 kPa.

When these design principles are met, the dilution refrigerator becomes insensitive to the exact PT2 stage temperature. In fact, because pulse tube cooling power increases with temperature, the system can accommodate significantly higher heat loads.

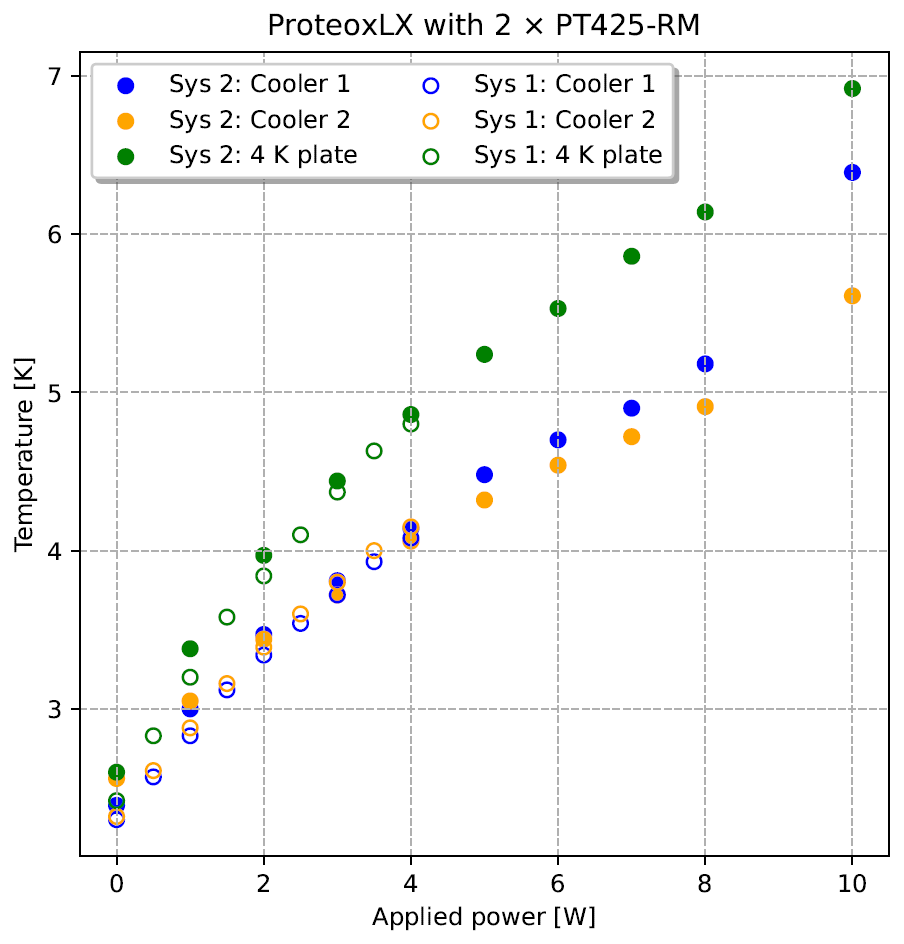

In recent tests, shown below, the Proteox system maintained 25 μW of cooling at 20 mK while dissipating over 10 W at the 4 K stage , operating with the PT2 plate above 6.5 K. This demonstrates substantial thermal headroom without compromising millikelvin performance.

Note: As the PT2 temperature rises, the total heat load on the still (from conduction through the system support structure, and from the returning 3He) increases. However, this can be offset by simply reducing the electrical heater power delivered to the still heater that is used to drive the 3He circulation.

Figure 1: The image above shows the system temperatures of the pulse tube coolers and the dilution refrigerator '4 K' stage as power is applied to a heater on the fridge plate. This test was again conducted whilst the dilution refrigerator continued to supply 25 μW of cooling power at 20 mK at the mixing chamber stage.

The Proteox platform’s ability to maintain robust millikelvin performance while accommodating elevated PT2 temperatures and high 4 K heat loads is a testament to its thermal efficiency. This flexibility not only simplifies integration of complex experimental setups but also enables cost-effective scaling of quantum systems.

Have a question? Reach out to our ULT experts and get the answer.

Contact us to learn more about the Proteox family of dilution refrigerators