Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

In conversation with Delft Circuits

Continuing our engagement with companies in the quantum ecosystem, we spoke to Daan Kuitenbrouwer, CCO & Co-Founder of Delft Circuits, to find out more about how their technology is compatible with different cryogenic systems, including Oxford Instruments’ Proteox range of dilution refrigerators.

So, who is Delft Circuits?

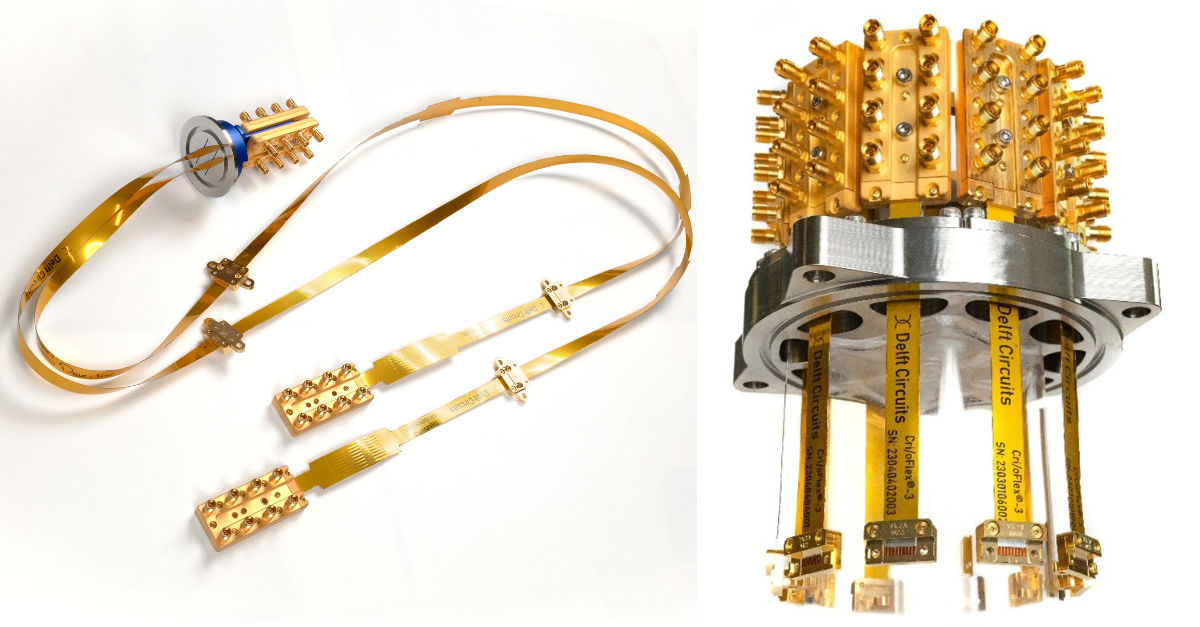

Based in Delft, The Netherlands, Delft Circuits is dedicated to accelerating the quantum industry by enabling i/o technology. We develop, design, manufacture and test all our i/o assemblies, based on our Cri/oFlex® (CF) technology with (superconducting) high-frequency flex technology. We sell our products to various labs and companies across the world and have our own flex manufacturing facilities where our team of 40 people works.

Daan Kuitenbrouwer

Harriet van der Vliet

Interviewer

Could you tell us a bit about the wiring solutions you provide?

Cri/oFlex®, our fully integrated i/o solution provides high density microwave channels from room temperature to the low-temperature stage within the limited available space in a cryostat, whilst keeping a low thermal footprint.

We design our products with the application in mind. For example, superconducting- and spin qubit systems require various types of filtering in the i/o chain. With our flex technology, we integrate attenuators, low-pass filters and IR filters in the flex. This allows us to avoid breaking out to filter blocks at every temperature stage and thereby reduces the number of interfaces. This makes the system less complex, less prone to failure and easier to install.

Are these solutions easily compatible with our Oxford Instruments Proteox dilution refrigerators?

There are a variety of ways that our solutions are compatible with Oxford Instruments’ dilution refrigerators. For smaller ports, such as KF40 or KF25, currently a limited number of standard SMA connectors and semi-rigid coaxial lines can fit per port. Cri/oFlex® expands the capability of these ports by being able to fit more channels in the same amount of space. Alongside this, Cri/oFlex® does not require line-of-sight ports due to its flexible nature. This expands the use of multichannel flexible microwave lines, to the non-line-of-sight ports on cryostats.

Another way that the Cri/oFlex® is compatible, is through upgrades of installed dilution refrigerators. Unutilised ports on previous Oxford Instruments’ dilution refrigerators, the Triton range of systems, can be filled with Cri/oFlex®.

Cri/oFlex® is designed to bring the next level of high-density i/o solutions to the market with increased line density at competitive pricing.

What is your vision of the quantum ecosystem?

As an i/o company, providing key components in the value chain of the quantum ecosystem is of vital importance for us. We believe that, just as in any other industry, the most successful quantum computer builders will be those that most effectively integrate building blocks from different vendors. For us to thrive, we thus must ensure excellent interfacing with the cryogenic suppliers such as Oxford Instruments.

To that end, we have, together with other Dutch startups, founded ImpaQT with the following vision: ‘An industry can only be as mature as its value chain’. One of its first activities is to collaborate on standardized and open interfaces.

How has your product been adopted by the quantum computing community?

Customers think of cables as a part of the system that ‘should just work’. So first, we have carried out thorough microwave- and thermal measurements on our cables at our premises. But of course, the real test is on actual qubits. We have carried out several tests with different parties here in Delft as well as with our customers elsewhere and see that the qubit performance with Cri/oFlex® is the same as with coax. Stay tuned for our publication on an overview of these results.

What is next for Delft Circuits?

i/o consists of three parts:

Up to this point, we have managed to create an i/o platform that is very well capable of transmitting and conditioning (1+2) signals in a confined space and with very limited thermal load. Our current interfacing solutions are based on SMA and SMP connectors. These connectors are fine for limited numbers of interconnects, but these become a bottleneck above ~500 channels.

For our product to reach its full potential we are working on methods to interface both to the chip as well as to the control hardware. In line with the value chain philosophy, we are collaborating and open to collaborating with different solution providers to build these interfaces.

About Delft Circuits

Delft Circuits is a Dutch company providing high-density i/o solutions for the quantum industry with a specific product focus on quantum computing. Its product lines are built around Cri/oFlex®, which is a scalable i/o platform based on flex technology. The Cri/oFlex® platform combines a small form factor with low thermal load and integrated components. For this platform, both superconducting and normal materials are available. Due to its flexibility, Cri/oFlex® fits all Oxford Instruments fridges whether for bringing thousands of channels into the cryostat or upgrading older cryostats. For more information visit: https://delft-circuits.com/