Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

Matt Martin

Managing Director and Director of Engineering at Oxford Instruments NanoScience

Dr John Burgoyne

Head of Product and Marketing at Oxford Instruments NanoScience

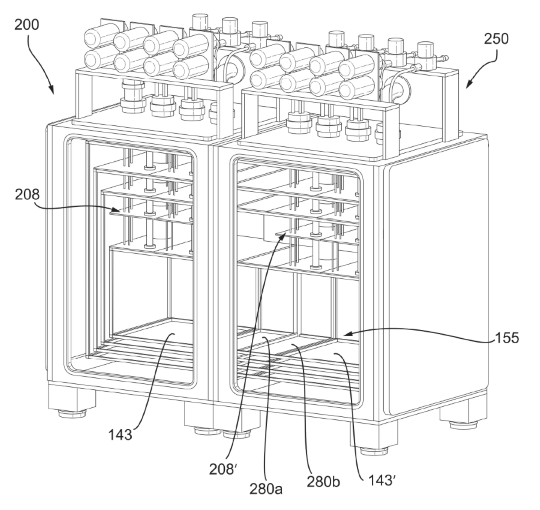

We are excited to announce the grant of a patent recognising the significance of the NanoScience approach to large modular dilution refrigerators for quantum computing. The granting of US patent no. 12,320,557 B2 on 3 June, 2025 covers the inter-connection of multiple rectangular-format dilution refrigerator systems, with connection not only of vacuum vessels to form a single multi-system contiguous vacuum space, but also of the multiple cold plates of the dilution refrigerator. This unique and now patent-protected technology opens the way for square-metres of cold real estate including at milliKelvin temperature, allowing quantum processing unit (QPU) interconnection without having to route wiring outside of the cryostat to ambient, room temperature connections between systems.

Matt Martin, Managing Director and Director of Engineering at Oxford Instruments NanoScience describes the importance of this breakthrough for large-scale quantum computing.

Quantum computing scale-up of superconducting qubit devices will require continuous low temperatures of 10-20 mK for quantum processor operation, necessitating the use of dilution refrigerators. It is acknowledged that traditional cylindrical designs of dilution refrigerator cannot scale to the qubit numbers needed for fault-tolerant quantum computing (FTQC). Non-cylindrical geometries have been promoted for compact data-centre-ready footprint and improved access to the dilution refrigerator cold stages. However a square, rectangular or even hexagonal geometry does not itself solve the problem, without the ability to connect systems in the way described in this patent. We took this multi-system scalability into account from the start when developing our ProteoxQX large-format, 1,000-plus qubit capable system, and designed for both efficient footprint and inter-connection.

That’s correct. In April we we announced the installation of the first two ProteoxQX systems. Putting these large-scale systems into customer hands was an exciting milestone, but only the beginning.

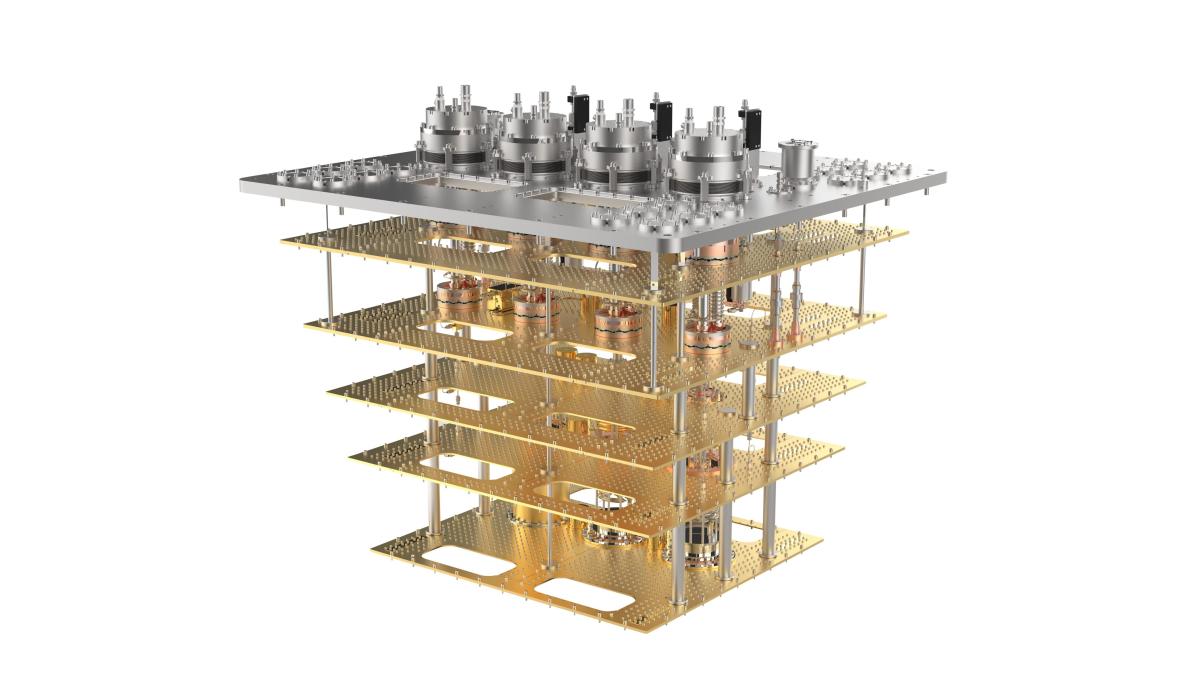

Yes, we did indeed. Scalability is one of the key features of the ProteoxQX design, with a fully accessible workspace over 3 m tall and over 1.5 m wide. Its square shape means that systems can be connected very easily for a single continuous vacuum space. But beyond that connection, the systems can be configured by the customer either to connect cold plates to give a large continuous mixing chamber, or to maintain separately controlled mixing chamber spaces. This flexibility of configuration allows the ProteoxQX to grow and adapt as users' QPUs expand, protecting the investment and following the customer’s technology journey.

The patent validates the innovation of the NanoScience team, and our ability to engineer solutions to meet the challenges of quantum computing scale-up. I am very proud of that team, but even more excited to be able to offer customers a unique solution to their quantum scaling and FTQC roadmaps.

The patent captures our novel approach to provide a fully modular system, allowing the customer system to be scaled up in the steps they wish, increasing space and total cooling power as they do so. This also means that a customer can build the size of their system incrementally by connecting additional modules and can manage their capital expenditure profile.

Our modular design also makes ProteoxQX it easier to service – an important uptime consideration. For example, a user may only need to remove part of thermal shielding for a given module to access the relevant space.

We see these as all being critical enablers of future quantum computer server farms.

A key feature across the Proteox dilution refrigerator family is the side-loading secondary insert, which carries the QPU control and read-out wiring. Our smaller format ProteoxMX carries one secondary insert, appropriate for qubit and initial QPU development. The mid-scale ProteoxLX has two secondary inserts, so allowing the next steps in scale-up and implementation, as has been proven in multiple real-world data centres. These side-loading secondary inserts allow pre-characterisation and modification of wiring and other cold components, and a seamless route to scale from development to implementation by transferring the validated wiring across systems as the QPU qubit number increases. The ProteoxQX platform also follows this modular growth pathway, having either four or six removable secondary inserts, offering unrivalled flexibility and 1,000-plus qubit capability.

Contact us to learn more about the Proteox family of dilution refrigerators