Applications

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Expand

Collapse

By Daniel Strange, Principal Magnet Engineer and Ben Bryant, Senior Development Engineer at Oxford Instruments NanoScience

Oxford Instruments NanoScience is built on superconducting magnets. When founders Sir Martin Wood and Lady Audrey Wood attended the first International Conference on High Magnetic Fields in 1961 in Cambridge, Massachusetts, the buzz around the potential of superconductivity had reached elevated heights. It had been shown that a simple coil of wire and liquid Helium could generate fields of up to 30+ Kilogauss, and it was at this conference that the two founders decided to embrace this new superconducting technology in the then two-year-old Oxford Instruments.

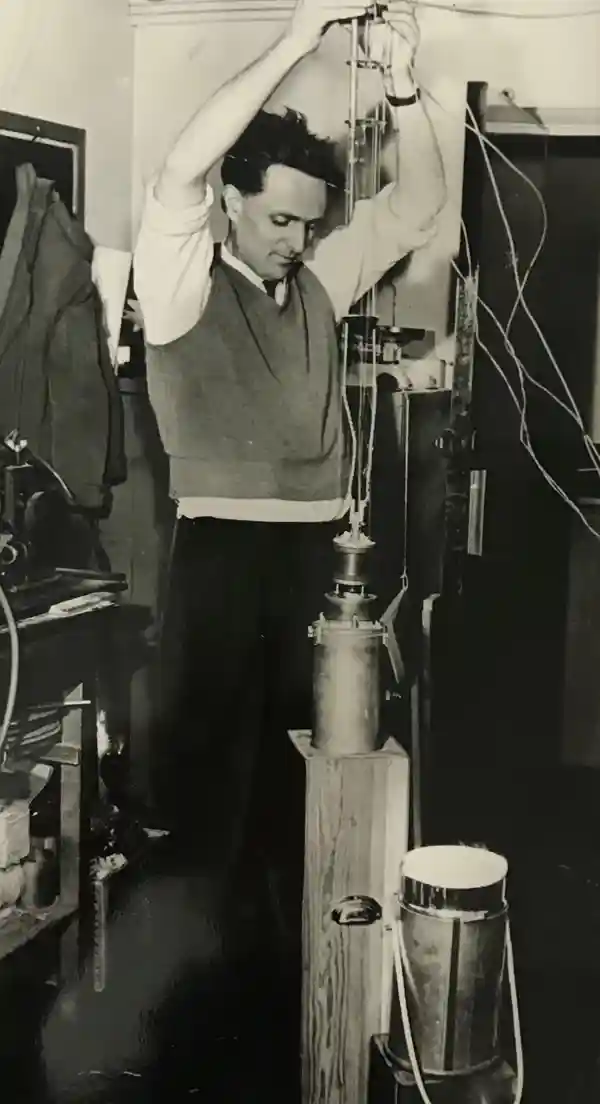

The first commercially available superconducting magnet was produced by Oxford Instruments only one year later. Sir Martin even designed and hand wound the magnet himself, powering it with his car battery and a rheostat. Then in 1971, the first superconducting MRI magnet was produced here and, eight years after that, NMR magnets became widely commercially available.

With over 6o years’ experience, Oxford Instruments has developed a comprehensive magnet department, designing solenoid, split pair, and vector rotate magnets that encompass helium-recondensing, Cryofree® and “wet" liquid helium-cooled magnets. Our solenoid magnet systems, compatible with the Proteox, Teslatron and Integra systems, can reach magnetic fields of up to 20 T at 4.2 K. Our split pair magnets achieve fields up to 15 T, with applications that span neutron scattering, magneto-transport measurements, low dimensional physics, spintronics, high-field magnetisation and optical spectroscopy. The vector rotate magnets, which are integrated in our Proteox and Teslatron systems, offer the ability to rotate the magnetic field in up to three axes.

Sir Martin Wood testing the first superconducting magnet

Oxford Instruments' split pair magnet

With such a range of magnets available, the applications they span are also broad: from solid-state NMR, EPR and ESR, to experimental X-ray applications using split pair magnets and to dark matter and particle physics research. Our magnets can be found deep underground in mines, in almost every beamline facility around the world, at the tops of mountains in observatories, and have even been sent into space by the European Space Agency.

Oxford Instruments’ magnets are designed based on decades of development and technical expertise. This makes them incomparable when it comes to reliability, quality, and performance. With a high energy density, our magnets have less mass and an overall lower cost of operation. This smaller mass can also result in faster cooldowns and quicker experiment turn-over, maximising productivity and value. All magnets are factory tested and characterised to ensure quench-free operation. Active magnetic shielding options can make systems safe to operate in compact laboratory environments and these shields can also be optimised to give low-field regions for experimental purposes. Our in-house design capabilities allow whole systems to be created by Oxford Instruments. This ensures optimised and seamless integration between magnet and cryogenics providing a streamlined customer experience and reliable and accurate experiments.

The depth of expertise and engineering experience of superconducting magnets and cryogenic systems enables us to create custom-engineered solutions. Flexibility and adaptability to client’s needs is extremely important: no business or institution will have the same budget, application, or experimental parameters. With this in mind, our helium-recondensing, Cryofree® and “wet” liquid helium-cooled magnets can be integrated into the solution that best suits the customer, the application, and the magnet design requirements. Bore sizes are also customisable beyond the typical range of 52mm to 90mm. With the help of specialist teams, customers can adapt their system specification and design according to their priorities and budget to develop a realisable and successful project.

Oxford Instruments’ Vector rotate magnet